Научный метод расчета срока службы аккумулятора погрузчика основан не на времени, а на максимальном количестве разрядов, которое может выдержать аккумулятор.

Расчетный срок службы аккумуляторов для вилочных погрузчиков обычно составляет 1600 циклов.

Это означает, что после 1600 циклов зарядки и разрядки зарядная емкость аккумулятора падает ниже 80% от заводского значения, и аккумулятор считается непригодным к использованию и должен быть выброшен или заменен.

Не знаете, как выбрать аккумулятор для погрузчика? Не знаете, как обслуживать разные типы аккумуляторов? Найдите экспертную информацию здесь:

https://www.lifttops.com

чтобы помочь вам решить все проблемы со свинцово-кислотными аккумуляторами.

Благодаря развитию технологий и широкому ассортименту вариантов выбор аккумулятора для вилочного погрузчика может оказаться непростой задачей. Существует несколько типов аккумуляторов, подходящих для погрузочно-разгрузочных работ: от традиционных свинцово-кислотных до литий-ионных, водородных топливных элементов и других. Чтобы получить необходимую мощность, необходимо понимать принципы работы каждой технологии и её потенциальные ограничения.

Для разного оборудования могут потребоваться разные типы аккумуляторов в зависимости от области применения, условий окружающей среды и требований к устойчивому развитию. Чтобы помочь вам понять, какая технология может подойти для вашего случая, эта статья содержит краткое описание некоторых решений по электропитанию, включая их преимущества и недостатки. Хотя это, безусловно, не заменяет консультации эксперта по электропитанию, которые могут быть полезны для вашего конкретного объекта и ситуации, эта статья поможет вам составить общее представление о доступных вариантах.

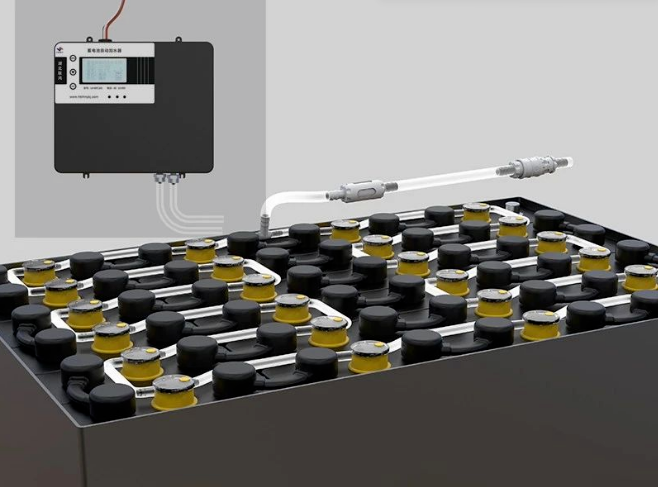

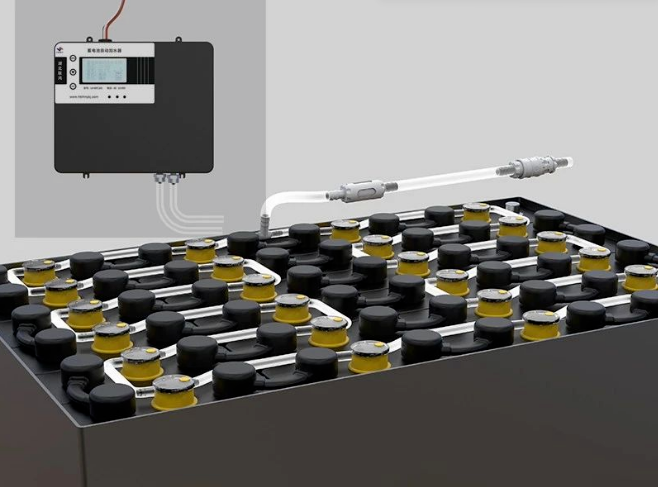

Свинцово-кислотные аккумуляторы выпускаются двух типов: с плоскими пластинами и трубчатыми плоскими пластинами.

В плоских свинцово-кислотных аккумуляторах токопроводящие положительные пластины расположены в сетчатой структуре, напоминающей соты, а энергия вырабатывается посредством химической реакции свинца и серной кислоты. Плоские модели очень устойчивы к высоким токам зарядки. Проще говоря, чем быстрее заряжается плоская модель, тем короче срок службы аккумулятора. В большинстве случаев плоские аккумуляторы остаются хорошим выбором для небольших однопластинчатых операций, особенно при подъеме тяжелых предметов.

Трубчатые батареи отличаются от плоских батарей конструкцией положительной пластины.

Вместо сетчатой сотовой структуры трубчатые аккумуляторы имеют выступы, вертикально простирающиеся вниз, в электролит. Они окружены цилиндрическими или квадратными гильзами, заполненными активным материалом, образующими трубчатую структуру. Такая конструкция обеспечивает большую площадь поверхности для взаимодействия свинца положительной пластины с кислотным электролитом, что приводит к несколько большей ёмкости аккумулятора по сравнению с аналогичным аккумулятором с плоскими пластинами. Помимо примерно 15% увеличения ёмкости аккумулятора, трубчатая конструкция также немного эффективнее принимает заряд, чем конструкция с плоскими пластинами.

Вот некоторые общие характеристики, присущие всем моделям свинцово-кислотных аккумуляторов:

01

Расходы

На первый взгляд, свинцово-кислотные аккумуляторы кажутся самым экономичным вариантом на рынке. Трубчатые аккумуляторы примерно на 10% дороже плоских свинцово-кислотных. Однако необходимо учитывать расходы, связанные с помещением для зарядки аккумуляторов и другими требованиями к обслуживанию.

Как правило, стоимость покупки свинцово-кислотного аккумулятора, будь то плоский или трубчатый, составляет лишь около 30% от общей стоимости владения. Срок службы свинцово-кислотного аккумулятора зависит от многих факторов, включая качество аккумулятора, способ и частоту его использования, процедуры зарядки пользователем и качество используемого зарядного устройства, обслуживание аккумулятора и условия эксплуатации (как высокие, так и низкие температуры оказывают значительное влияние на срок службы свинцово-кислотного аккумулятора). В зависимости от всех этих факторов большинство свинцово-кислотных аккумуляторов обеспечивают надежное питание вилочного погрузчика в течение 1200–1800 циклов зарядки и разрядки, или от трёх до семи лет. В некоторых случаях, когда нагрузка очень низкая, аккумуляторы могут даже прослужить 10 лет и более при условии надлежащего обслуживания.

02

Требования к зарядке

Стандартные свинцово-кислотные аккумуляторы заряжаются медленнее, чем альтернативные, при этом эффективность зарядки составляет от 75% до 75% в зависимости от технологии зарядного устройства и состояния аккумулятора. Это означает, что количество заряда, за которое вы платите, не соответствует количеству, которое в конечном итоге поступает в сам аккумулятор. Эта неэффективность процесса зарядки приводит к выделению тепла, что требует более длительного охлаждения между использованиями. Хотя последние достижения в области зарядных технологий позволили сократить время зарядки свинцово-кислотных аккумуляторов, многие ограничения всё ещё существуют, включая необходимость еженедельной выравнивающей зарядки.

Ну, вот и все, что мы хотели сказать сегодня. Если у вас есть какие-либо технические вопросы или вам нужны какие-либо запчасти для вилочного погрузчика, пожалуйста,

связаться с нами!

русский

русский русский

русский English

English français

français español

español português

português العربية

العربية

IPv6 поддерживается сетью

IPv6 поддерживается сетью